SOLUTION

Comprehensive solution

Steel Billet Continuous Casting Production Line

In the process of producing various steel products in steel plants, there are two methods of using molten steel to solidify and form: the traditional die casting method and the continuous steel casting method.

DetailsRolling mill is the equipment to realize the metal rolling process, generally refers to the equipment to complete the whole process of rolling material production.

DetailsCasting refers to the processing method of melting solid metal into liquid and pouring it into a mold of a specific shape, and waiting for it to solidify and form.

DetailsContinue Casting Direct Rolling

Continue Casting Direct Rolling (CCDR), is pouring liquid steel into a continuous casting machine to cast a billet, and then without cooling, keep it in the soaking furnace for a certain period of time, and then directly enter the hot continuous rolling unit for rolling and forming Steel rolling process.

DetailsADVANTAGE

Full Babysitting Service

R & D Team

20 years of industry experience, with a team of experienced and skilled engineers

High quality and low price

Our products are mostly imported from advanced original factories, which not only have low costs but also guarantee quality

Service Assurance

Service personnel are available 24/7 to provide you with technical guidance

ABOUT

Who We Are

Luoyang Ruixinsheng Industrial Technology Co., Ltd. specializes in induction melting and heating equipment manufacturing, research, development, sales and integration of high-tech enterprises. The company's research team has long cooperated with national and international universities and institutes. Each product has its own intellectual property rights, and they are derived from the entire team's more than 20 years of innovation and experience accumulation in the induction furnace industry.

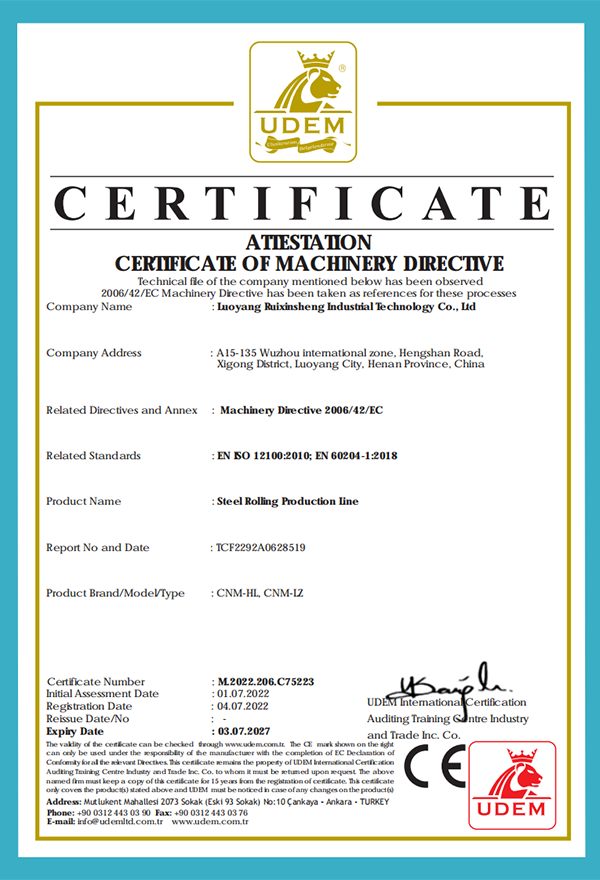

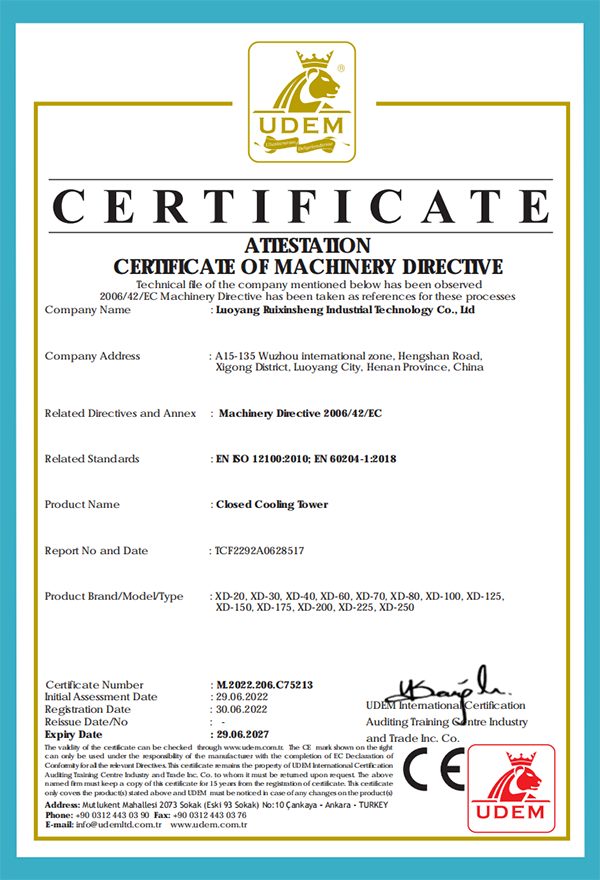

Learn moreQUALIFICATIONS

Scientific research innovation

CE

CE

CE

ISO9001

ISO9001

CE

CE

CE

ISO9001

NEWS

Learn About Our Dynamics

Thank You for Your Attention to Ruixinsheng !

service innovation seek development, create value and enjoy win-win.Send us your needs for your business, we have professional service team to answer you !