Products

-

-

Non-ferrous Metal Casting And Rolling Machine

-

-

Fully Automatic Induction Heating System for Forging Forming

-

Induction Heating Heat Treatment and Tempering Production Line for SteelPipe and Oil Casing

-

Induction Heating Heat Treatment Quenching and Tempering Production Line for Finished Thread Steel

-

Induction Heating Heat Treatment Production Line for Mine Grinding Rod

-

Heat Treatment and Tempering Production Line of Construction Machinery Cutter Angle Plate

-

Production Line for Tempering and Heat Treatment of Steel Plate and Special Key

-

Tempering and Tempering Production Line for Induction Heating of Steel Bars

-

Large Diameter Seamless Steel Tube Induction Heating and Tempering Heat Treatment Production Line

-

Continue Casting Direct Rolling

hiddenValue

- Product description

-

Overview

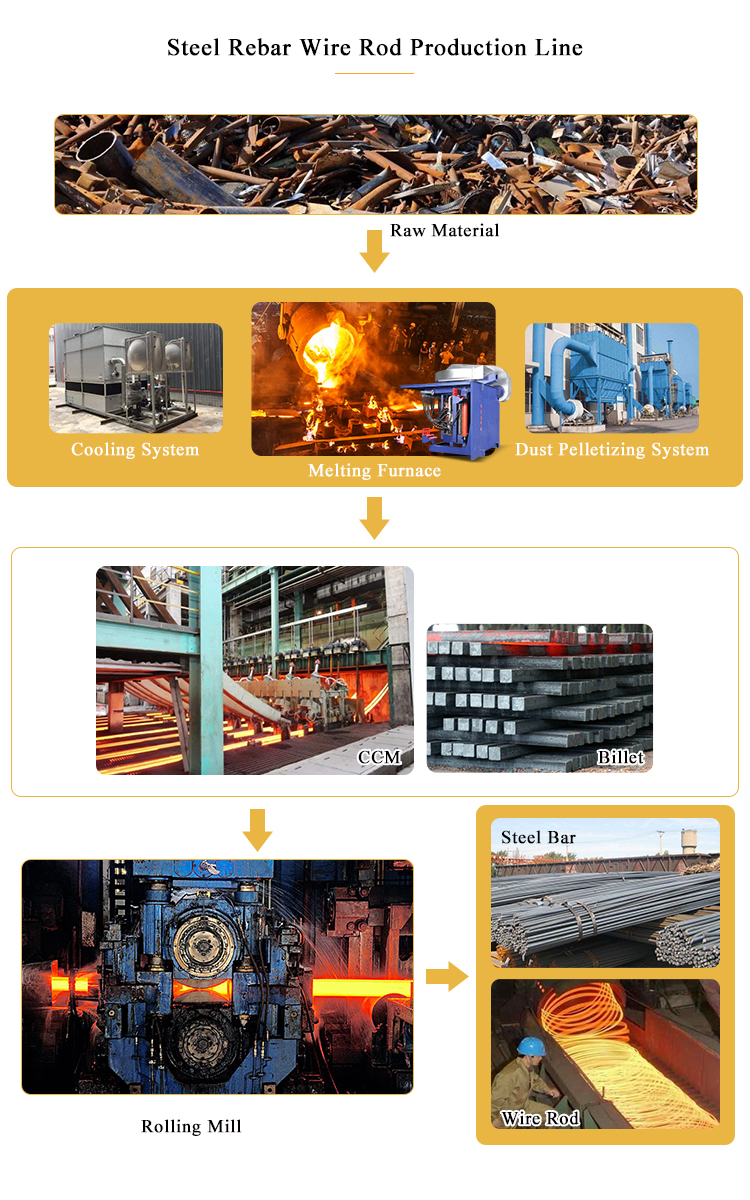

Continue Casting Direct Rolling (CCDR), is pouring liquid steel into a continuous casting machine to cast a billet, and then without cooling, keep it in the soaking furnace for a certain period of time, and then directly enter the hot continuous rolling unit for rolling and forming Steel rolling process.

This process skillfully combines casting and rolling. Compared with the traditional process of first casting a billet and then heating it in a heating furnace before rolling, it has the advantages of simplifying the process, improving working conditions, increasing metal yield, It has the advantages of saving energy, improving the quality of continuous casting slabs, and facilitating the realization of mechanization and automation.

Process flow

1. Put the molten steel into the ladle and lift it to the top of the continuous casting machine by the crane;

2. The molten steel in the ladle is injected into the continuous casting machine for continuous casting production, and the continuous casting slab is pulled out from the bottom of the continuous casting machine;

3. The continuous casting slab is cut to length by flame cutting, and the continuous casting slab cut into a fixed length is sent into the soaking furnace;

4. The continuous casting slab advances slowly in the soaking furnace to ensure that the temperature of the continuous casting slab is uniform and constant;

5. The continuous casting slab comes out of the other end of the soaking furnace and enters the hot continuous rolling mill for rolling;

6. The rolled and formed steel enters the water cooling section for quenching treatment;

7. After quenching, the steel enters the walking cooling bed for cooling;

8. Finally collect, cut to length, and pack.

Why Choose Ruixinsheng Technology?

Independent Intellectual Property Rights:

Master the core technology and independent research and development of internationalleading induction heating system.

Energy-Saving and Efficient:

Meet international standards for electrical and load design standards, power factor up to0.98, and energy saving 20%.

Environmental Protection and Safety:

Furnace structure according to the national standards, scientific and technologicalreasonable personalized design, ensure the safety and reliability of the device.

Stable and Reliable:

The world's first-class component selection, scientific and reasonable equipmenttechnology, complete protection functions, the primary fault is close to zero.

Intelligent Control:

Equipment management system, can achieve production management, quality control andother functions, to achieve remote diagnosis of equipment, data acquisition, transmissionand other monitoring.

Send Inquiry

Tell us your needs, and we will recommend you the melting furnace that suits you.

Related Product