Products

-

-

Non-ferrous Metal Casting And Rolling Machine

-

-

Fully Automatic Induction Heating System for Forging Forming

-

Induction Heating Heat Treatment and Tempering Production Line for SteelPipe and Oil Casing

-

Induction Heating Heat Treatment Quenching and Tempering Production Line for Finished Thread Steel

-

Induction Heating Heat Treatment Production Line for Mine Grinding Rod

-

Heat Treatment and Tempering Production Line of Construction Machinery Cutter Angle Plate

-

Production Line for Tempering and Heat Treatment of Steel Plate and Special Key

-

Tempering and Tempering Production Line for Induction Heating of Steel Bars

-

Large Diameter Seamless Steel Tube Induction Heating and Tempering Heat Treatment Production Line

-

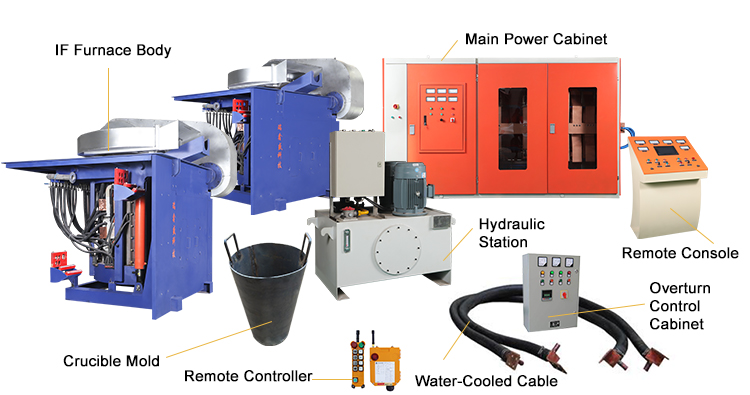

Stainless Steel Induction Melting Furnace

Capacity: 0.1T-15T

Melting Time: 40mins-60mins

Material Acceptable: Stainless Steel, Steel

Tilt Type: Hydraulic

Configuration: Melting Body, Control Cabinet

hiddenValue

- Product description

-

Stainless steel melting furnaces are mainly used in the production process of stainless steel. Stainless steel raw materials (such as scrap steel, stainless steel alloy elements and other metal materials) are melted at high temperatures for alloying, smelting and refining to obtain stainless steel of the required composition and quality. It plays a core role in the manufacturing process of stainless steel and is widely used in the steel industry, metallurgical industry and metal recycling. Specific uses include:

Stainless steel production: Melt scrap steel and stainless steel alloy materials to form stainless steel liquid for casting and subsequent processing.

Alloying and tempering: Through the melting furnace, add different alloy elements such as chromium, nickel, molybdenum, etc. to adjust the composition of molten steel to ensure that stainless steel has the required physical and chemical properties.

Scrap steel recycling: Used for the melting and recycling of stainless steel waste, regeneration treatment, and reprocessing of waste stainless steel products through high-temperature melting.

Refining treatment: Desulfurization, dephosphorization, impurity removal and other refining operations are carried out through the melting furnace to improve the purity and quality of stainless steel.

Why Choose Ruixinsheng Technology?

Independent Intellectual Property Rights:

Master the core technology and independent research and development of internationalleading induction heating system.

Energy-Saving and Efficient:

Meet international standards for electrical and load design standards, power factor up to0.98, and energy saving 20%.

Environmental Protection and Safety:

Furnace structure according to the national standards, scientific and technologicalreasonable personalized design, ensure the safety and reliability of the device.

Stable and Reliable:

The world's first-class component selection, scientific and reasonable equipmenttechnology, complete protection functions, the primary fault is close to zero.

Intelligent Control:

Equipment management system, can achieve production management, quality control andother functions, to achieve remote diagnosis of equipment, data acquisition, transmissionand other monitoring.

Send Inquiry

Tell us your needs, and we will recommend you the melting furnace that suits you.

Related Product