Products

-

-

Non-ferrous Metal Casting And Rolling Machine

-

-

Fully Automatic Induction Heating System for Forging Forming

-

Induction Heating Heat Treatment and Tempering Production Line for SteelPipe and Oil Casing

-

Induction Heating Heat Treatment Quenching and Tempering Production Line for Finished Thread Steel

-

Induction Heating Heat Treatment Production Line for Mine Grinding Rod

-

Heat Treatment and Tempering Production Line of Construction Machinery Cutter Angle Plate

-

Production Line for Tempering and Heat Treatment of Steel Plate and Special Key

-

Tempering and Tempering Production Line for Induction Heating of Steel Bars

-

Large Diameter Seamless Steel Tube Induction Heating and Tempering Heat Treatment Production Line

-

Longitudinal Billet Heating Furnace

hiddenValue

- Product description

-

Overview

Billet induction heating (supplementary heat) system mainly consists of power transformer, power supply equipment, inductor, transmission machinery, straightening equipment, speed regulating equipment, automatic control system, protection, detection system, heat soaking, heat preservation system, etc.

Advantage

These devices should be effectively and systematically connected through the automatic control system. Purpose: One is the need for the connection of continuous casting and rolling systems, and the other is to achieve precise control to maximize benefits and minimize energy consumption. The third is to reduce the number of operating personnel. If the heating equipment is well designed, it can be operated without personnel.

Application

Medium frequency induction heating is one of the ideal products for the connection between continuous casting machine and rolling mill. The intermediate frequency heating system can not only effectively improve efficiency and reduce energy consumption, but also effectively avoid the disadvantages of excessive oxidation slag, environmental protection, and site problems caused by flame heating.

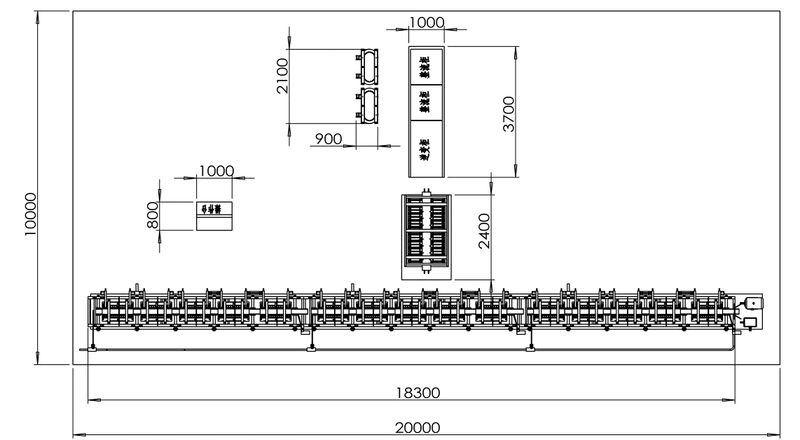

Reference drawing

Longitudinal Billet Heating Furnace is a highly efficient equipment specially used for heating treatment of steel billets.

1. Structural features

Furnace structure

Longitudinal Billet Heating Furnace has a reasonable longitudinal layout, and the furnace body is built with high-quality refractory materials. These refractory materials can effectively resist high temperatures, reduce heat loss, and ensure the stability of the temperature in the furnace. The furnace shell usually adopts a solid metal structure with good sealing to prevent heat overflow and abnormal convection of air.

Heating system

The heating elements are arranged scientifically. Advanced heating technologies such as resistance heating or induction heating are adopted. Resistance heating converts electrical energy into thermal energy through a high-resistance heating element, which can provide stable heat output. Induction heating uses the principle of electromagnetic induction to generate eddy currents inside the billet to achieve rapid heating of the billet with extremely high heating efficiency.

2. Performance advantages

Heating uniformity

Relatively uniform heating can be achieved in both the length direction and the cross-sectional direction of the billet. This helps to ensure the quality stability of the billet during subsequent processing, for example, there will be no stress unevenness caused by local temperature differences during rolling.

Accurate temperature control

Equipped with an advanced temperature control system, the furnace temperature can be accurately set and adjusted. The temperature is monitored in real time by sensors and fed back to the control system. The control system automatically adjusts the heating power according to the set value to ensure that the temperature fluctuation is controlled within a very small range.

High efficiency and energy saving

Due to its reasonable structure and advanced heating technology, Longitudinal Billet Heating Furnace has a higher energy utilization rate than traditional heating furnaces. In large-scale billet processing and production, it can significantly reduce energy costs.

High degree of automation

It can realize automatic linkage with upstream and downstream equipment. From the feeding of billets to the discharging after heating, the entire process can be operated by an automated control system, which reduces manual intervention and improves production efficiency and safety.

Longitudinal Billet Heating Furnace is widely used in industries such as steel manufacturing and is a key equipment for improving billet processing quality and production efficiency.

Why Choose Ruixinsheng Technology?

Independent Intellectual Property Rights:

Master the core technology and independent research and development of internationalleading induction heating system.

Energy-Saving and Efficient:

Meet international standards for electrical and load design standards, power factor up to0.98, and energy saving 20%.

Environmental Protection and Safety:

Furnace structure according to the national standards, scientific and technologicalreasonable personalized design, ensure the safety and reliability of the device.

Stable and Reliable:

The world's first-class component selection, scientific and reasonable equipmenttechnology, complete protection functions, the primary fault is close to zero.

Intelligent Control:

Equipment management system, can achieve production management, quality control andother functions, to achieve remote diagnosis of equipment, data acquisition, transmissionand other monitoring.

Send Inquiry

Tell us your needs, and we will recommend you the melting furnace that suits you.

Related Product