Products

-

-

Non-ferrous Metal Casting And Rolling Machine

-

-

Fully Automatic Induction Heating System for Forging Forming

-

Induction Heating Heat Treatment and Tempering Production Line for SteelPipe and Oil Casing

-

Induction Heating Heat Treatment Quenching and Tempering Production Line for Finished Thread Steel

-

Induction Heating Heat Treatment Production Line for Mine Grinding Rod

-

Heat Treatment and Tempering Production Line of Construction Machinery Cutter Angle Plate

-

Production Line for Tempering and Heat Treatment of Steel Plate and Special Key

-

Tempering and Tempering Production Line for Induction Heating of Steel Bars

-

Large Diameter Seamless Steel Tube Induction Heating and Tempering Heat Treatment Production Line

-

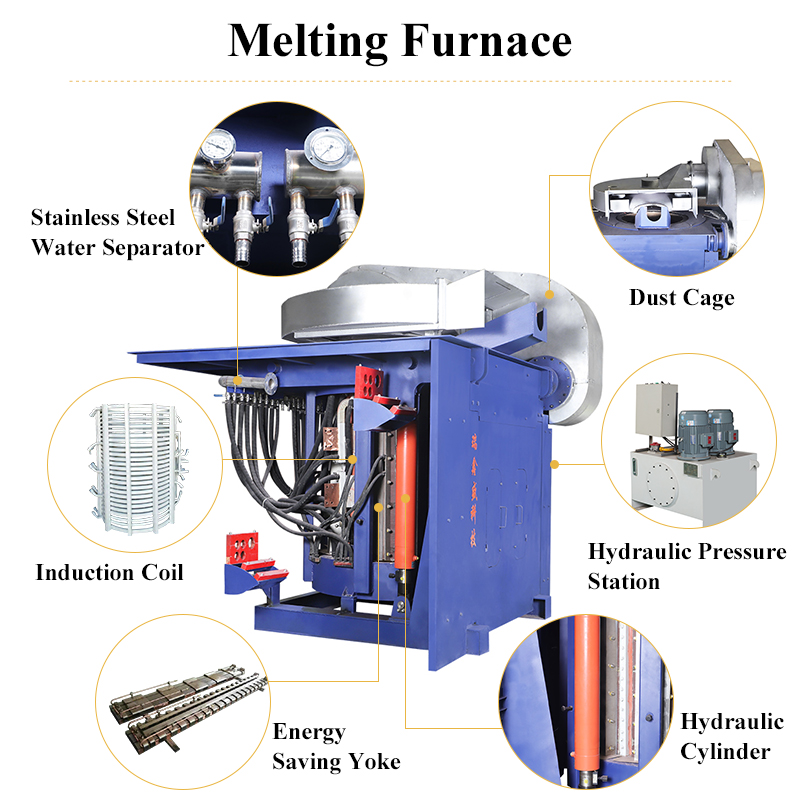

One Tow Two Induction Melting Furnace

hiddenValue

- Product description

-

Application

Mainly used for smelting cast iron, stainless steel, alloy steel, non-ferrous metals, including heavy metals (such as copper, lead) and precious metals (such as gold, silver), etc. The equipment is used in metallurgical industry, casting industry, non-metal smelting and other industries.

One tow two melting furnace work features

The operation mode adopts one tow two, one tow two, that is, one power supply cabinet supplies two furnace bodies to work at the same time. It can also be operated by any set of equipment separately and supplied to the A and B furnaces. It is especially suitable for large-scale continuous production operation of small and medium-sized castings, high-power melting operation of any electric furnace, and another furnace body can keep warm or preheat the cold furnace. The power is arbitrarily distributed as needed, and the sum of the powers of the two electric furnaces is constant. P = P (A) + P (B).

The two electric furnaces are continuously alternately melted and insulated for simultaneous operation, so that the power supply can always run at full power. This working mode works with two power supplies of one power supply, which greatly reduces the capacity of the transformer

Advantage

1. Energy saving, saving 20% than ordinary equipment;

2. No high-order harmonics, no need to eliminate harmonic devices;

3. The power factor is high, the power factor is always maintained above 0.95, without the reactive power compensation device;

4. The high utilization rate of the transformer can save half of the transformer capacity.

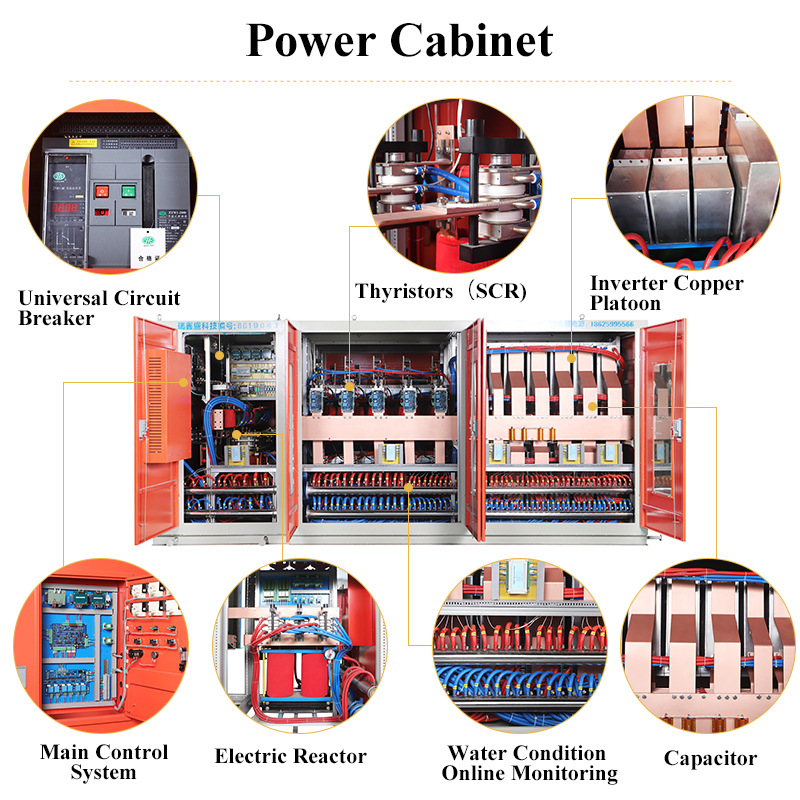

Power Supply

This melting furnace can realize fully automatic remote control, including PLC programmable controller, HMI man-machine interface or industrial control computer system, industrial control configuration software and various sensors. It can realize automatic operation, such as automatic constant temperature, automatic oven and furnace leakage alarm, which is safer and more convenient to use.

The power advantage

1. Through a single power supply device, realize the mass production capacity of multiple furnaces.

2. Uninterruptible melting and accurate thermal insulation or overheat temperature control.

3. It can preheat, sintering, melting and ultra-low power insulation for multiple electric furnaces at the same time.

4. Each furnace adopts independent control system.

5. Can provide full constant power to one furnace while isolating the other under maintenance.

6. Just one set of power connection and water connection, greatly reducing installation, operation and maintenance costs.

7. The latest generation of digital operation technology, Single Clip Microcomputer program control.

8. Lower starting frequency, ultra-low power oven.

9. Full open rectifier, high power factor, Higher harmonics are small.

10. The equipment power utilization rate is close to 100%.

11. Liquid metal is more productive and does not need to increase electricity demand.

12. It can produce efficiently and match different metal liquid demand levels.

13. Optical fiber transmission trigger signal, electronic control using digital mode.

14. Very competitive power consumption indicator.

15. Comply with domestic and international electrical safety design standards.

16. More perfect and intelligent protection function.

Technical parameters of IFinduction melting furnace

Rated capacity (t)

Rated power (KW)

Rated frequency (HZ)

Transformer configuration

Pulses

IF voltage

Melting rate(t/h)

Energy consumption (kWh/t)

Capacity (KVA)

Secondary voltage (V)

(V)

0.25

250

1000

315

3φ380V

3

1500

0.25

700

0.5

400

1000

500

3φ380V

3

1500

0.5

660

0.75

600

1000

800

3φ380V

3

1500

0.75

650

1

800

1000

1000

3φ380V

3

1500

1

630

1.5

1200

500

1500

3φ660V

3

2400

1.5

620

2

1500

500

1600

6φ660V

6

2400

2

610

3

2200

500

2500

6φ660V

6

2400

3

610

5

3500

500

4000

6φ1000V

6

3200

5

600

8

5000

500

6000

6φ1000V

6

3200

8

600

10

6300

500

7000

6φ1000V

12

3200

10

600

15

9000

250

2×5000

2×6φ1000V

24

3200

12

565

20

11000

250

2×6300

2×6φ1000V

24

3200

15

560

30

14000

150

2×8000

2×6φ1000V

24

3200

20

550

40

18000

150

2×10000

2×6φ1000V

24

3200

25

540

50

20000

150

2×11000

2×6φ1000V

24

3200

30

530

60

22000

100

2×12000

2×6φ1150V

24

4000

35

520

70

25000

100

2×13000

2×6φ1400V

24

4600

45

510

Why Choose Ruixinsheng Technology?

Independent Intellectual Property Rights:

Master the core technology and independent research and development of internationalleading induction heating system.

Energy-Saving and Efficient:

Meet international standards for electrical and load design standards, power factor up to0.98, and energy saving 20%.

Environmental Protection and Safety:

Furnace structure according to the national standards, scientific and technologicalreasonable personalized design, ensure the safety and reliability of the device.

Stable and Reliable:

The world's first-class component selection, scientific and reasonable equipmenttechnology, complete protection functions, the primary fault is close to zero.

Intelligent Control:

Equipment management system, can achieve production management, quality control andother functions, to achieve remote diagnosis of equipment, data acquisition, transmissionand other monitoring.

Send Inquiry

Tell us your needs, and we will recommend you the melting furnace that suits you.

Related Product