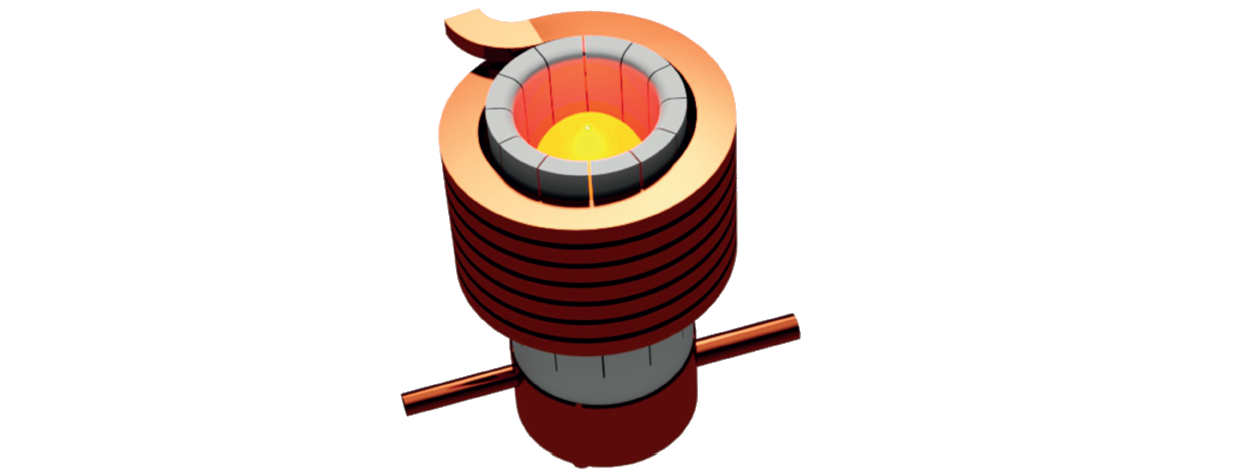

Cold crucible induction melter

Release time:

2025-08-20

The cold crucible induction melter is an advanced metal melting equipment. It utilizes unique induction heating technology and is primarily used for melting high-melting-point, highly reactive metals and alloys.

1. Product Overview

The cold crucible induction melter is an advanced metal melting equipment. It utilizes unique induction heating technology and is primarily used for melting high-melting-point, highly reactive metals and alloys. It plays an important role in the preparation of specialty metals, aerospace, and nuclear energy.

2. Working Principle

Induction Heating

The cold crucible induction melter operates based on the principle of electromagnetic induction. When an alternating current passes through an induction coil, it generates an alternating magnetic field within the crucible. Because metals are conductive, the magnetic field induces an induced current within the metal. According to Joule's law, the thermal effect of the induced current heats and melts the metal.

Features of the Cold Crucible

Unlike traditional crucibles, the cold crucible utilizes a water-cooling structure. During the melting process, the crucible walls are kept relatively low by water cooling, preventing excessive reaction with the highly reactive metal being melted. This structure also helps reduce crucible erosion and prolongs its service life.

3. Product Advantages

Pure Melting

The unique structure of the cold crucible and its induction heating method reduce impurities during the melting process. This ensures extremely high purity when preparing high-purity metal materials, such as reactive metals like titanium and zirconium.

Energy Efficiency

Induction heating directly affects the metal itself, resulting in highly efficient energy utilization. Compared to traditional furnaces, the cold crucible induction melter can melt metals in a shorter time, reducing energy consumption.

Precise Temperature Control

The melting temperature can be precisely controlled to meet the stringent temperature requirements of different metals and alloys, ensuring accurate alloy composition and stable metal performance.

4. Applications

In the aerospace industry, the cold crucible induction melter is used to melt specialty alloys for high-performance engine components. In the nuclear power industry, it is used to melt radioactive metals such as uranium and thorium. It is also an indispensable device for preparing new high-performance metals in the research and production of high-end metal materials.